Catalogs

|

Here is a link to the newest Bilz offerings - take a look!

|

|

The ThermoGrip® tool holding system uses an inductive heating concept to provide stronger, more-concentric tool clamping. This leads to increased tool life, better surface finishes and improved cost efficiency. Our offering covers machines, holders (including heavy duty), extensions, collets and accessories—everything you need to maximize profits!

|

|

Bilz tapping systems are used worldwide across a broad variety of machines in a multitude of applications. Bilz’s success is due to a continual process of development, constantly improving existing product lines and introducing innovative new products. Bilz created a de-facto tapping standard with the quick-change tapping systems in 1950.

Any threaded hole in any automobile manufactured today can be machined with a Bilz tapping holder. Many actually ARE machined with Bilz holders.

|

|

Bilz CNC holder products are made to the highest industry standards. The quality of our shank tapers and tool clamping systems are among the best in the industry. Whether it is BT, CAT, or HSK - Bilz has the tool shank and tool style to support your daily production needs with high performance tool clamping products ranging from End mill holders to Hi-Power Milling chucks with collet chucks in between. Included in this catalog are the Diebold Gauging Products to help you maintain your spindle taper accuracy, alignment, and tool shank clamping pressure.

|

Brochures

|

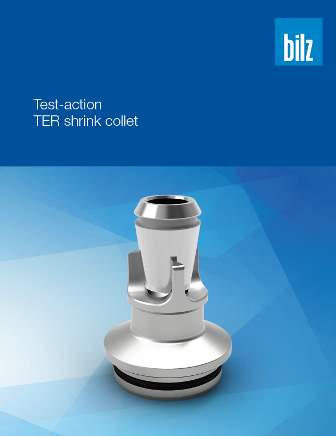

The TER shrink fit collets offer ridgid and strong holding power for angle heads or live tooling. Swiss turning machines benefit greatly from higher gripping forces and better runout accuracy - improve the productivity by up to 300%, and be able to hold extended length cutters that would not last in spring collets.

|

|

The STA tapping system offers synchro tapping capabilities inside standard collet chucks, angle heads or live tooling.

|

|

The Cool Jet bores allow coolant to be sprayed around the cutting edge, where the cutting tool does not have coolant bores.

|

|

The new Bionics shrink fit chucks allow a new way to clamp tooling with improved vibration characteristics. From extremely short tools to longer reach - the new chucks make your machining processes more efficient.

|

© 2024, ALL RIGHTS RESERVED. BILZ TOOL COMPANY, INC. 1140 NORTH MAIN STREET, LOMBARD, IL 60148 1-847-734-9390